Our company has many years of experience in the automation of the poultry slaughtering line. For years we have been cooperating with a company providing complete poultry slaughtering and cutting lines. Our systems successfully operate, among others in Poland, Ukraine, Kazakhstan, Lithuania, and Uganda. Based on the completed projects, we are able to provide automation systems for every device in a poultry slaughterhouse.

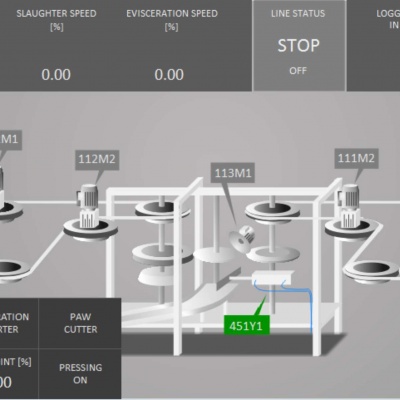

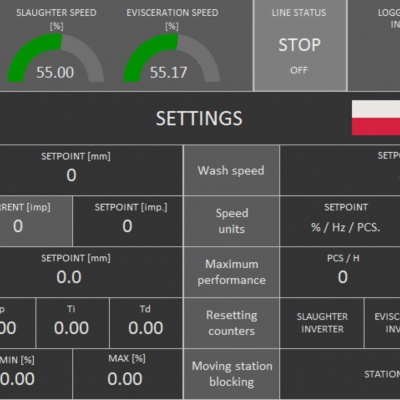

Examples of automated devices on the slaughter line are shown below.